Sasquatch. The Easter Bunny. Die cut tooling costs.

To the best of my knowledge, only one of these things exists (and the Easter Bunny agrees with me).

If you’re new to die cut converting, tooling costs can feel as mysterious as cryptids: seemingly hidden and potentially fabricated altogether. But unlike Bigfoot, tooling costs are very real and essential to the converting process.

When you’re looking at your quote for the first time, you may not realize it, but Strouse actually covers a significant portion of the tooling costs for our clients. Understanding what you're paying for will help you evaluate quotes and make smarter financial decisions for your project. Let’s look closer at what goes into these costs.

How Much Does a Die Cut Tool Cost?

The cost of a die cut tool depends on design complexity, material, and the quantity of parts. These factors can all determine the intricacy, durability, and steel quality of your tool.

THE COST OF PARTIAL TOOLING

If you’ve received a die cut quote from Strouse, you’ll know that you are responsible for covering “partial tooling.” Partial tooling is the initial cost of the die cut tool, and understanding why you pay this can clear up confusion in the quoting process.

WHY DO YOU PAY FOR DIE CUT TOOLING?

When you pay the initial cost of tooling, you’re paying for the rough cost of the tool itself. Every die cut tool is custom-made for a project, which is why you pay the initial cost.

Tooling costs encompass fabrication and maintenance. With Strouse, you usually only pay the initial cost.

Why is retooling necessary after the initial investment?

The blade of a die cut tool endures constant stress and dulls over time.

.png?width=1200&height=630&name=this%20could%20be%20the%20diagram%20of%20the%20tooling%20drawing%20scott%20made%20(2).png) Retooling is an inevitable part of converting. Once the die cut tool becomes dull enough to make faulty contact with the anvil, your converter will send it back to the tooling manufacturer for retooling—i.e., sharpening.

Retooling is an inevitable part of converting. Once the die cut tool becomes dull enough to make faulty contact with the anvil, your converter will send it back to the tooling manufacturer for retooling—i.e., sharpening.

The majority of die cut tools can undergo 3-5 retools before replacement. As the one using and maintaining the die cut tool, Strouse decides and subsequently handles necessary retooling.

HOW LONG DO DIE CUT TOOLS LAST?

Because die cut tools wear down over time, they eventually need to be either retooled or replaced. The lifespan isn’t fixed, but certain factors can help predict how often your tool will need to be replaced.

A die cut tool’s lifespan varies depending on:

-

-

What you’re cutting to

-

If your part design has many layers, you could cut all the way or partially through the material. Cutting all the way through, or “zero-clearance” cutting, will cause the blade to contact the metal anvil, which will cause it to dull faster. Kiss cutting, or partially cutting through the material, allows your blade to last longer.

-

-

What you’re cutting through

-

Die cut tools wear down much more quickly when you use highly abrasive materials. For instance, thermal transfer paper is a highly abrasive material with a tough coating. Because it’s difficult to cut, tooling manufacturers often build specialized tools for it entirely.

Another example of abrasive material is white ink, which contains titanium dioxide. Cutting white ink on a die cut press causes the tool to dull prematurely. In short, abrasive materials cause your die cut tools to wear down quickly, leading to higher overall tooling costs and more frequent retooling.

SHOULD YOU PREPARE FOR RETOOLING?

As your converter, Strouse will anticipate and prepare for eventual retooling.

You will likely pay only a partial tooling cost, as Strouse covers most retooling, maintenance, and other follow-up costs. The main exception in our tooling cost coverage is for design changes, which may require a different die tool entirely and are therefore not covered

Tooling Alternatives You Might Consider

Tooling costs are often a necessary evil in die cut production; however, there ARE a few alternatives.

Using non-production-based (a.k.a. flex tooling) or non-rotary tools can give you custom die cut parts without the high expense of standard, rotary die cut tooling.

NON-PRODUCTION-BASED TOOL (FLEX TOOLING)

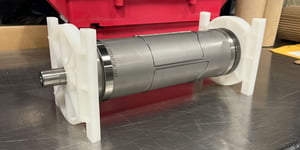

A non-production-based tool is a thin plate mounted to a cylinder full of magnets, and while it doesn’t last as long as a regular die cut tool, it has a lower initial cost.

When do you use flex tooling?

Flex tooling is often ideal for thin products like labels and prototype parts, which are typically characterized by low volumes or frequent design changes (i.e., those in development).

How much do flex tools cost?

The initial cost of flex tooling is significantly lower than that of standard tooling, sometimes up to 3x or 4x lower. In fact, many non-production-based tools cost less than $500.

High-quality steel dies are more expensive, but they last far longer and require fewer replacements. If you’re planning a high-volume, long-term project or need highly accurate final part tolerances, then regular, higher-quality die cut tools are likely the best fit for you.

What are the downsides of choosing flex tooling?

Of course, flex tooling also has many downsides, such as its thickness limit (typically only up to 20 mil), a shorter lifespan, limited repeat sizes, and less overall project versatility.

Flex tooling isn’t ideal for every project, and if you’re looking to elongate the lifespan of a die cut tool, you’ll want to instead focus on investing in high-quality steel.

LASER AND DIGITAL CUTTING METHODS

Laser and digital cutting methods don’t require the purchase of a die cut tool. Laser and digital cutting rely on the machines, so there is no tooling cost.

Many of our samples and prototypes are made on a laser or digital cutting machine because they don’t require us to order any rotary die cut tools. Yet, due to their limitations, non-rotary cutting tools aren’t ideal for every project or situation.

The downsides of laser and digital cutting

Firstly, these methods are often best for low-volume projects because they are much slower than some of their other counterparts, which results in a higher price per part. Secondly, many materials cannot be laser-cut, despite the fact that laser cutting can achieve tight tolerances.

Lastly, digital cutting machines don’t achieve as tight tolerances as the laser, but they can cut larger objects, so the cutting method you choose depends on your specific product needs and how we can help you achieve them.

How Partial Tooling Costs Can Help You

Die cut tools are expensive, and partial tooling saves you money by ensuring your converter takes care of your eventual retooling.

From tooling maintenance costs to die cut tool replacements, Strouse covers years of fees for each individual project. Some of our most active projects require retooling 1-2 times per month!

Reach out to see how much you’ll pay for tooling with Strouse. Assuming you plan to make a decent quantity of parts, you’ll absolutely benefit from the partial tooling system.

On the other hand, if your project is low-volume or a one-time production, you may want to try our aforementioned tooling alternatives for better cost efficiency.

Unsure which production method to use? Got any additional questions about manufacturing tooling costs? Schedule a project consultation, or check out our Learning Center for more information.

Originally published: February 15, 2023