How much does my project cost, and what affects the price?

Let's talk about the topic that other converters are avoiding

Your drawings, materials, processes, etc., are all unique to you. We cannot create a calculator to give you an exact price for your project.

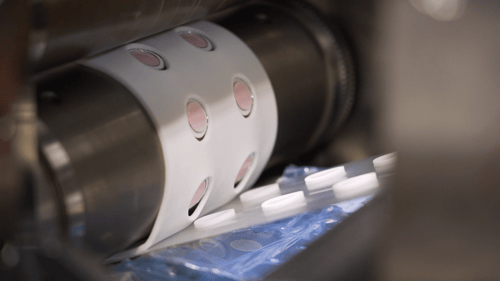

Die Cutting Project Costs

Die cutting projects can cost as little as $500 to millions of dollars per year, depending on the material, design, labor, quantity, and more. Each individual die cut part might range anywhere from fractions of a penny to over hundreds of dollars per part because the price per part is very volatile based on a few key factors.

To help you understand why there is such a massive range between die cut costs, allow us to explain what factors affect the die cutting process and how working with an experienced converter can help lower your price per part.

Factors that Drive the Price Per Part Up ⬆️

- Choosing expensive/challenging materials

- Designs with many layers

- Design intricacies and tight tolerances

- Low quantity orders (minimum order quantities and fixed costs drive the PPP up as quantity goes down)

Factors that Drive the Price Per Part Down ⬇️

- Using functional tolerances

- Optimizing your design (e.g., combining layers and more)

- Purchasing in roll form

- Buying in bulk

How Does Project Scaling Affect My Price?

| Quantity | Setup Hours | Setup Costs | Run Hours | Run Costs | Material Costs | Material Waste % | Total Cost | Price Per Part↓ |

|---|---|---|---|---|---|---|---|---|

| 1,000 | 10 | $500 | 10 | $500 | $23,750 | 60% | $24,750 | $24.75 |

| 5,000 | 12 | $600 | 48 | $2,400 | $23,750 | 10% | $26,750 | $5.35 |

| 10,000 | 14 | $700 | 95 | $4,750 | $23,750 | 5% | $29,200 | $2.92 |

| 100,000 | 20 | $1,000 | 950 | $47,500 | $158,333 | 1% | $206,833 | $2.07 |

This hypothetical part design being priced above is…

- A simple shape (4” x 4” footprint)

- Using 1 moderately priced material (additional materials create more waste due to increased part complexity)

- With an average of 200-300ft of material waste for setup

- With a Minimum Order Quantity (MOQ) of 10,000 parts worth of material

The MOQ plays a significant role in determining your price per part. As the chart above demonstrates, larger orders help justify the minimum order cost of materials. The percentage of wasted material decreases as the quantity increases because the setup material makes up a much smaller percentage of the total material.

At lower quantities, your waste percentage is significantly higher, giving you a significantly higher price per part. You are exponentially more efficient using the material at higher quantities. Once the high quantity order is up and running, it is the most efficient machine run due to having a more balanced proportion of material to parts; however, at some point, this will plateau at the lowest price per part possible.

What Does it Take to Get a Die Cutting Project Off the Ground?

Projects often begin with free samples, a handful of prototypes, or even rolls of material. This is sufficient to get through the early stages of a die cutting project.

However, once you start getting into functional testing and validation, the demand requirements typically increase, prompting you to start investing in the project. Below are several upfront costs realized during a new die cutting project.

Paid Samples

Depending on your stage in the product development process, you may need to test materials and designs. Paid samples (often 100-200 parts) are typically produced on our flat bed laser or using a digital knife.

Pricing and lead times can vary depending on design, tolerance, material, etc. We will have to learn more about the product and application before we can advise pricing and lead time.

Although the price per part will be higher than full-scale production due to a smaller quantity, the overall cost will be lower since using a laser or digital knife costs less than a rotary die cutting machine.

Hard Tooling

Die cut tools can cost anywhere from a few hundred to thousands of dollars, depending on the quantity and complexity of your design.

Lower quantity projects with simpler designs may require less expensive tools than the alternative. While Strouse typically covers part of the tooling cost, the initial cost is yours.

Is Die Cutting Worth the Cost?

While the initial cost of a custom die cut project can be a significant investment, taking the first step is an excellent way to establish an existing manufacturing process for your design. If you’re still unsure whether die cutting is a possibility, get a custom quote from our team to help you decide.

Custom Slit Roll Costs

Much like die cutting, custom slitting costs are made up of materials and labor. However, the factors are a bit different.

Material Cost

Let's say that you have already planned your process; you may only need the right materials to get started.

The cost of materials is affected by the following:

- Availability factor

- The type of material and adhesive you use

- Formatting (number of rolls, size, etc.)

- Minimum Order Quantities

Strouse offers material sampling and sourcing services, as well as boxed goods. However, we do not manufacture our own flexible materials in-house, so we recommend planning for a multi-week lead time to be on the safe side.

Credit Options

If you are looking for terms options, below is what we offer. This is based on a credit reference we will request before acknowledging your first purchase order.

Full Payment Upfront

50% Upfront, 50% at Shipment

Full Payment at Shipment

Net 30 Terms

Got any additional pricing questions? Please reach out to us today!

.png?width=300&name=What%20Goes%20Into%20(28).png)

.png?width=300&name=What%20Goes%20Into%20(13).png)