/Delta%20ModTech%20Edge%203.jpg?width=300&name=Delta%20ModTech%20Edge%203.jpg)

Capabilities

Unsurpassed design, true innovation, pure problem-solving

This Is The Precision Converting You’ve Searched For

Your project is our focus; the right shape and size, and packaged the way you need it. Put industry-leading adhesive tape manufacturing processes and tight-tolerance die cutting to the test.

/Delta%20ModTech%20Edge.jpg?width=300&name=Delta%20ModTech%20Edge.jpg)

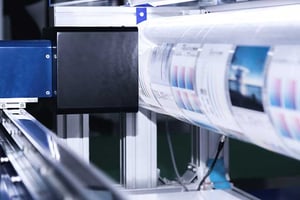

Customized Presses

Our commitment to precision die cutting can reach extreme levels. We customize our presses for each job’s needs, meaning we alter each piece of machinery, allowing for specific capabilities. Plus, our customers appreciate our in-line vision systems, which allow us to 100% inspect parts in real time as they run through presses.

Just-In-Time Inventory Management

Call it “lean manufacturing” or “Toyota production system” or “JIT (just-in-time),” it all means an inventory strategy that lowers inventory carrying costs, increases efficiency, and decreases waste. We order inventory for production only when needed to produce goods, which keeps costs low for our customers.

More Than Tape

We feel the same way you do: it’s not just buying tape; it’s designing adhesive solutions that drive positive business outcomes. We use whatever is needed — advanced web converting presses (see above), clean manufacturing environments, robust processes — to ensure tight-tolerance, precision die cutting of tapes, foils, films, and many other adhesives.

Buyer's Guide to Die Cut Parts

Navigating the complexity of material conversion can be frustrating and confusing. We've created this guide based on our years of unparalleled expertise in turning ordinary materials into extraordinary manufacturing solutions.

You cannot afford mistakes, which cost time, money, and reputation. Download this guide to start avoiding all of them.

%20(1)-modified%20(2).png?width=300&name=buyers%20guide%20realistic%20vers%20(2)%20(1)-modified%20(2).png)

What do our customers think?