-1.png?width=300&name=My%20project%20(4)-1.png)

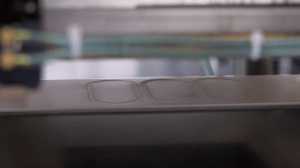

FLAT BED DIE CUTTING

Simple and Effective

Flat bed die cutting uses custom-shaped blades to stamp out parts like cookie cutters. A converter places the custom-fabricated die tool in a hydraulic or mechanical flat bed press, where matching slots beneath allow for a clean cut and easy removal of the finished piece.

Converters can easily change tools and achieve cuts with fewer edge deformities using this method.

Request a Quote Learn More About Die Cutting

What is Flat Bed Die Cutting Used For?

Manufacturers use flat bed die cutting to build various products, including:

- Custom gaskets or seals

- Medical device components

- Thermal and acoustic insulation materials

- EMI/RFI shielding materials

- Interior and exterior automotive parts

and many other products.

Plan your project budget.

The Benefits of Flat Bed Die Cutting

- Cuts thick and sheeted materials

- Tools can be changed easily and quickly

- Excellent for low-volume projects

Flat bed die cutting is arguably the most basic method of die cutting material. It offers an effective solution for low-volume projects or those not conducive to rotary technology.

We can help you select the right method for your needs.

Get a Flat Bed Cutting Quote

Provide us details in the form and we can get you a quote for your product.

- What Product Are You Looking For?

- What Size/Dimensions?

- Quantity You Will Order

- Information on How the Material Will Be Used

- Problems You May Have Encountered When Using this Material