Frequently Asked Questions

Does Strouse issue products for individual use?

If you are an individual (not a business) seeking a small quantity of tape or products for personal use, our business is likely not suited to your application.

Hard tooling costs can range from hundreds to thousands of dollars, so the cost of full-scale production might be disproportionate to your needs.

Which tape should I use?

Your material choice will depend on your design and its application. We can help you source the right material to build a solution, but first, we'll need to understand your application:

- How tight are your functional tolerances?

- What environmental conditions will the material be exposed to?

- Do you need it rolled or sheeted?

- Are you using Low-Surface Energy (LSE) materials?

- Do you need to be worried about material or adhesive outgassing?

Approaching us with this information prepared will make finding a suitable material a far quicker and smoother process.

NOTE: Strouse does not sell individual products or liquid adhesives. We do not offer technical support for 3M products or any other products.

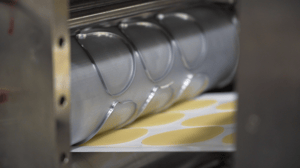

Does Strouse sell die cutting machines and hard tooling?

We do not sell die cutting machines or hard tooling. While Strouse does offer complex die cutting services, our machines and tooling are purchased from other companies.

Do you have products in stock?

As a custom goods manufacturer, we typically only carry material for current jobs. We can acquire boxed goods upon request, but for singular rolls, you'll want to contact a vendor.

What do I need in order to qualify for samples?

If you haven't yet acquired a drawing for your custom product, then it's likely too early for a design prototype. Once you have a detailed technical drawing that is ready to be prototyped, then you may proceed to sample-making and/or quoting.

Is there a Minimum Order Quantity for a job with Strouse?

It depends. While Strouse technically doesn't have an official MOQ, we have found that smaller orders will climb in price due to production costs, which might not suit your needs. Some of the more complex orders may need to reach a press minimum of $500-1000 to ensure they're cost-effective, but this is determined on a case-by-case basis.

How long is the quoting process?

The quoting timeline will vary depending on your design complexity and our access to material pricing. Part of this time is spent comparing pricing to get the best value for your dollar, which might involve reaching out to multiple vendors. Providing ample information about your design and its application will help our production quoting process.

I'd like to automate, where do I start?

You can prepare to automate your process by determining the level of automation you're seeking, your desired volume, and the complexity of your part design. This automation guide will help you plan as you look for new ways to scale and optimize your production process.

How do I know when I should switch converters?

If you're thinking about finding a new converter, keep an eye out for the following signs:

- Sluggish lead times

- Quality issues and defective parts

- Poor communication

There are many reasons why converters might struggle with all of the common problems listed above. Unfortunately, these issues often cause significant profit loss. Discussing your solution with another converter can be a helpful way to see whether there is room for improvement in your current process.

What services do you offer?

Our services can be found on our Capabilities page.