.jpg?width=300&name=59_4027%20(1).jpg)

Adhesive Foam Tape

Adhesive foam tape provides temporary or permanent bonding, whichever you need for your application.

From mounting objects to padding them for vibration & sound absorption, Strouse’s diverse manufacturing capability will provide you with the exact size, shape, and formatted foam required for your design.

What is Foam Tape?

Foam tape is a pressure-sensitive adhesive tape that can be single- or double-sided and comes in various lengths, thicknesses (1 mil to 375+ mil), and styles.

The strength and durability of foam tape makes it a popular choice for commercial and industrial applications. It's made up of three parts:

- Foam carrier — acrylic, polyester, polyethylene, polypropylene, or urethane

- Adhesive — typically acrylic or rubber-based

- Release liner — peels off for easy application

Permanent vs Temporary Foam Tape

Foam tape is a great alternative to screws, rivets, and other heavy fasteners. You can use foam tape to create a permanent bond that spreads the stress load across the entire length of the tape rather than the individual screw or rivet.

- Permanent foam tape can be used for heavy-duty solutions (e.g., foam sealing tape or foam gasket tape).

- Removable foam tape is ideal for temporary application challenges, such as indoor joining, nameplate mounting, point-of-purchase signage, retail shelf price channels, and pen holders.

Foam Tape Quality Standards

Foam tapes used in the medical or electronics industry may have specific quality requirements.

- Medical manufacturers use foams to bond medical device components together or to secure dressings directly to skin while providing cushioning.

- Electronics manufacturers use thin foam tape to bond assemblies and attach LCD and touchscreens.

Depending on your needs, you may need to seek out a manufacturer with a Clean Room or certain ISO standards.

Automotive Foam Tape

Foam tape is a high-bondage, lightweight solution for affixing vehicle upholstery, attaching sidewall panels, providing sound dampening, vibration absorption, and more.

Double-sided foam tape is an automation-friendly staple of modern automotive manufacturing and assembly. Whether applied by hand or by machine automation, Strouse can design a solution that is customized to fit in with your existing processes.

Medical Foam Tape

Foam tape can be used for stick to skin, sealing, device attachment, and many other medical use cases.

Medical manufacturers often use foam tape (polyethylene, silicone, or VHB) in medical device gasketing applications due to its ability to withstand pressure, liquids, and sterilization.

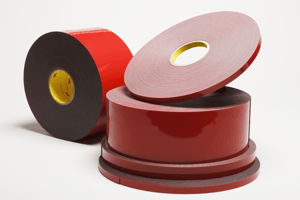

3M VHB TAPE

3M™ VHB™ Tape is a thin, lightweight, yet powerful foam tape that helps engineers bond electronics assembly components.

VHB is available in different forms for specific applications; some for high surface energy bonding (glass and metals), some for low surface energy substrates (plastics). Primerless acrylic foam tapes help automotive manufacturers reduce costs and reduce health risks to employees.

Trusted Material Suppliers

Strouse sources double sided tape from leading adhesive manufacturers, including 3M, Tesa, Berry, MacTac, FLEXcon, Adhesives Applications, and others.

Think foam tapes can bring your product to market faster? Want to explore the possibilities? Contact us today!

.png?width=300&name=Untitled%20(78).png)

.png?width=300&name=Untitled%20(77).png)

.png?width=300&name=Untitled%20(81).png)

.png?width=300&name=Untitled%20(82).png)

.png?width=300&name=Untitled%20(85).png)