If you’ve ever been in a discussion with a converter about die cutting, you might’ve heard the phrase “kiss cut” before. Funnily enough, you’ll find that asking about the difference between die and kiss cutting is the equivalent of asking about the difference between a square and a rectangle.

Kiss cutting is a critical manufacturing technique that Strouse and many other flexible material converters use daily. It is a type of die cutting in which a blade does not cut all the way through to the anvil (this would be called “through cutting”).

Before you solidify your production process, you should consider how kiss cuts AND die cuts will help you manufacture designs for streamlined assembly processes.

What is Kiss Cutting (with Examples)?

Kiss cutting, also known as “pressure-sensitive cutting,” is a type of die cutting where the blade does not penetrate the entire stack of material but instead cuts through a precise number of layers..png?width=1200&height=430&name=Adhesive%20(5).png)

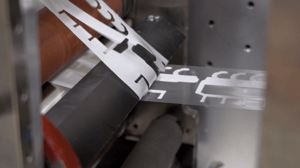

By adjusting the pressure between the die cut tool and the material underneath, a converter can create a setup where the die's sharp edges only penetrate to a certain depth. Calculating the slicing depth to the millimeter allows us to remove the top layer of material and leave behind a specific shape attached to the backing.

For instance, when building a sheet of stickers, the blade goes through the sticker layer with the design but stops before puncturing the liner, allowing the sticker to remain on the intact backing.

Ultimately, kiss cutting facilitates complex product creation with accessible features (tabs, crack and peel liners, etc.) that enable easy peeling.

Kiss Cut vs. Die Cut

Referring back to our analogy, all squares are rectangles, but not all rectangles are squares. All kiss cutting is a type of die cutting, but not all die cutting is kiss cutting.

Die cutting punches specific shapes from sheets of raw material as they run through the factory press. Depending on the tooling of each project, die cuts can be either kiss cuts or through cuts. Combining these methods will result in a finished product with its main body attached to the liner.

Kiss Cut vs. Through Cut

Unlike kiss cuts, through cuts (a.k.a. metal-to-metal cuts) pass through ALL the layers of a material and make contact with the metal anvil.

| NAME | Kiss cuts | Through cuts |

|---|---|---|

| DESCRIPTION | The blade does not penetrate the entire stack of material, but instead cuts through a precise number of layers. | The blade passes through a stack of material completely. |

| ADVANTAGES | Creates part features such as tabs, split liners, etc. | Punches out individual products from rolls of material. |

| DISADVANTAGES | Requires close monitoring and careful adjustments throughout the production process. | Metal-to-metal cutting tends to dull the die tool more quickly. |

In short:

- Kiss cuts are a die cutting technique where the blade NEVER passes all the way through.

- Through cuts are a die cutting technique where the blade ALWAYS passes all the way through.

Kiss cutting is a suitable choice if you need to cut specific layers of material. Combined, these methods can consolidate the steps of an otherwise long and tedious manufacturing process.

THE DIFFERENT FORMS OF KISS CUTTING

Kiss cutting and through cutting aren’t limited to a rotary die cut press, and can be implemented in alternative die cutting processes such as laser or flash cutting.

Laser kiss cutting uses a weakened laser to make shallow cuts in a material.

Because the laser's power is adjustable, an operator can lower the beam strength so it doesn't cut all the way through. Depending on the project, however, a laser might not be the ideal tool to use in certain situations because it involves searing off material, which may have dire consequences for certain adhesive materials (i.e., liquifying them).

Kiss Cutting Considerations

While kiss cutting can be an excellent die cutting method for boosting project efficiency, it is not simple for every project or material.

1. IT REQUIRES CLOSE MONITORING

Kiss cutting requires close monitoring so that each cut is made precisely. If done incorrectly, it might render products imperfect or even unusable.

If the kiss cut is too shallow, which may be difficult to spot initially, the product might not work. However, if the cut is too deep, the adhesive can enter the gap and cause problems between the material and its backing. It can also cause “deep die strikes,” which leave an imprint on the liner below the material.

2. INCREASED RISK OF IMPERFECT ROLLS

Defective kiss cutting may create imperfect rolls that are sloppy in the placement of their parts due to shifting during the delivery process. These imperfect rolls also risk possessing inconsistent tension, which might hinder any automation the product needs to undergo.

Build an Effective Manufacturing Process with Strouse

If you believe die cutting is right for you, it’s time to find a converter who can help. Before you dive into production, the first step is to review your part design and application with a converter to optimize production.

A skilled converter will help you plan an efficient manufacturing process that prioritizes your design's functionality.

Reach out to start your project with Strouse. With over 38 years of converting experience, we can help you successfully bring your prototype to production.

For more information about die cutting, check out our Learning Center.

Originally published: July 19, 2022