Are assembled components more cost-efficient?

Part of our work as flexible material converters is helping clients optimize their production process. Strouse has helped multiple companies with their automated assembly in the past, so we can provide insight into different strategies.

If you have a device made with multiple components, you’re likely facing the question of whether you get individual components or you get them pre-assembled. This article will help you navigate that decision-making process.

What is Individual Component Sourcing?

Individual component sourcing refers to the individual layers required for an assembled product being delivered to you as individual, discrete parts. You would determine how these components would be assembled through your own manufacturing automation to create completed final products.

What is Assembled Components Sourcing?

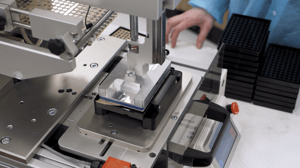

Assembled components sourcing refers to completed part assemblies being delivered to you. These assemblies are completed final products comprised of all the necessary individual layers and require no additional assembly effort from you.

Pursuing Individual Components vs. Assembled Components

Take a moment to consider your current product assembly process. Is there any automation involved? Are there points where assembled components may benefit you more than assembling your own individual components? Let’s compare some of the main differences.

1. COST OF SET-UP

Sourcing individual components is typically the lowest part-cost option. The combined cost of all the individual component layers is almost always lower than that of a single assembled component. This additional cost is due to the additional manufacturing effort associated with the complexity of combining layers in the converting process.

Of course, material sourcing isn’t everything. You might be thinking. “What are the differences in the production costs?”

Adversely to part cost, your production costs are lower when sourcing a single, assembled component. This production cost difference occurs because minimal additional production costs are required to get your product in your customers’ hands. Single assembled components are frequently supplied, packaged, labeled, and ready to sell.

2. SCALABILITY

Sourcing assembled components is typically the most scalable option. The converter will create parts in an efficient, automated process, and since you have minimal production requirements yourself, there are fewer barriers to scale.

Sourcing individual components would require significant scaling efforts on your part. These efforts are application-specific and wide-ranging. This range includes everything from substantial increases in labor resources and training for manual assembly to costly/time-consuming custom automation equipment.

If you see a high volume in your future, sourcing assembled components is an option you should explore.

3. PRECISION TOLERANCES

When it comes to part tolerances, there are many factors to weigh in favor of sourcing individual components vs. assembled components.

Assembled components typically provide the best option for maintaining precision tolerances; however, your tolerances may be too tight for this to be a feasible manufacturing option for your product. For this reason, we recommend discussing tolerances with your converter as early in the design phase as possible.

What is the Best Solution For You?

The choice between sourcing individual components and assembled components depends on many factors such as production volume, design complexity, budget, and timeline.

Planning for the assembly process and ensuring manufacturing feasibility of your design are crucial in making the right decision for your business. Engaging with a converter early in the design process is the best way to ensure you make the right choice for you and your product.

Finally, our Learning Center has more information if you’re looking for more automation resources.

Originally published: October 12, 2023