The most reliable bonding adhesive, 3M 200MP, is now paired with newly developed release liners that allow for easy application and the most accurate tight tolerance die cutting the industry has to offer.

Westminster, Maryland - June 30, 2014 - For the last 30 years 3M 200MP adhesive has set the standard for bonding adhesives . 3M 200MP is an acrylic adhesive that bonds substrates from high surface energy plastics to metals for every industry. This proven adhesive can be found in any application ranging from medical devices and electronics to automotive and appliance parts. 3M 200MP will now be constructed using new 3M technology - layflat liners, available at Strouse today.

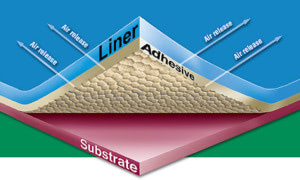

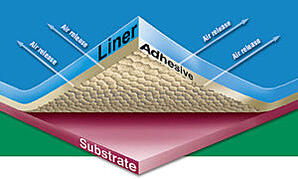

New 3M technology, microchannel liners create an escape path for trapped air when adhesive is applied to a surface.

New 3M technology, microchannel liners create an escape path for trapped air when adhesive is applied to a surface.While 3M 200MP has been a standout product for the last 30 years, the product has had a tendency to be difficult to work with when exposed to humid environments. High humidity can be problematic for any sort of flexible material, but especially acrylic adhesives. High levels of humidity in storage, processing and converting, shipping, and final product usage can alter the final converted part resulting in product failure. Curled parts, tunneling or buckling, edge scalloping, cockling, and rippling adhesive all are defects seen on acrylic adhesives once subject to high humidity conditions. 3M’s new layflat liner solves each of these issues.

The new 3M layflat liner will be the standard liner supplied on 3M 200MP adhesive. Layflat liner is a special polycoated paper construction that improves dimensional stability when exposed to high humidity environments. The new liner also improves sheet processing and productivity and creates a more precise die cut part that will not curl. Layflat liner ensures a consistent and uniform coverage of adhesive for a stronger bond.

Strouse is a die cut adhesive manufacturer with over 25 years of industry experience. Serving the medical, automotive, military, appliance, and renewable energy industry, Strouse continues to innovate. With a quality management system currently registered to ISO 9001:2008 standards, Strouse not only has a commitment to quality but excellent customer service. A full team of design and development engineers allows Strouse to invest the necessary time and resources for each and every project. Located in Westminster, Maryland, Strouse can be contacted directly at 1-800-410-8273 or visit our website for more info at https://www.strouse.com

.jpeg?width=290&name=0%20(1).jpeg)